A friend asked me how OffGRiD is coming along; here’s where things are at:

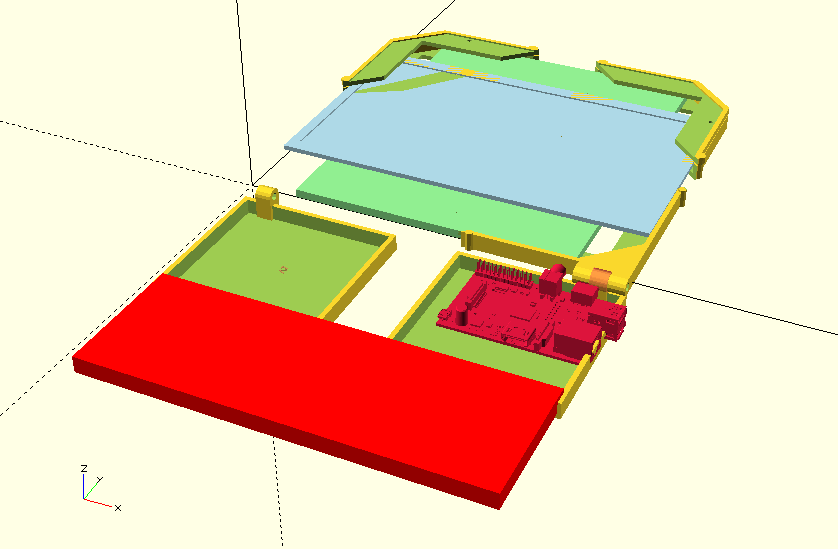

I’ve designed a lot of the case and started printing off some parts to see how they fit together and get a feel for the real-world size of the thing.

I’m pretty happy with the way things fit and I’m honestly surprised that things matched-up when I laid them out together with placeholders for the off- the-shelf parts.

At this point I think I’m running out of things I can do without getting my hands on the components, especially the solar panel and display. I’ve been working from the manufacturer’s specs, but they don’t tell me everything I need (or are completely missing for some of the parts). It’s also hard for me to really get a feel for the stuff without having it on-hand, and stuff like cable routing, etc. is hard (at least for me) to model in CAD.

The big barrier to getting the parts is the cost. All-in it’s about $500.00 in components and I’d like to have some spares/alternatives just in case. I’m considering doing a little crowfunding campaign to raise some R&D funds but I don’t want to get distracted from the project itself to run the campaign, so I’m still looking for alternatives.

Longer-term something I’ve been noodling on is a way to help people who are interested in a computer like OffGRiD get their hands on one. I don’t want to get into mass-producing them (it goes against some of the design goals to do so) but I did think of a way to make it more accessible for a broader range of people.

Once I have a working prototype or two, I’m thinking about creating a website where you can build-our your own personalized OffGRiD-style computer by selecting the off-the-shelf components (display, processor, battery, etc.) and have the site generate a Bill of Materials (BOM) for the off-the-shelf parts and then a collection of custom printable files for the case, keyboard, etc.

From there you can download the BOM & printables and source them yourself, or place an order for the components directly on the website (sourced from companies we like to support) and also send the printable files to a 3D printing company like 3D Hubs, Shapeways, etc.

This leaves assembly to the user, which is OK but I’d also like to partner with regional maker/hackerspaces so a person has options on finding local help, or setting up “build nights”, etc.

It’s a fairly ambitious project in it’s own right, but I don’t think too much so. It’s something I don’t want to dive into until I know that I can actually design a machine that works (and is pleasant to work with) so the prototypes come first, but I think it’s good to have an idea of what’s next for a project, especially one that requires a substantial up-front investment in time & resources.

--

// jjg