Harbor Freight folding utility trailer

A few weeks ago, I assembled the Harbor Freight Heavy Duty Folding Trailer (Item #62666) with my brother and father (and a little extra help, but more on that later). There’s a lot of information about this trailer on the Internet so I’ll focus on the things that I wasn’t able to find out there.

The size of the shipping boxes

This seems like something that should be right on the Harbor Freight website, but for some reason it was really hard to find out how big of a box the trailer comes in. Given its final size, I assumed it would be huge. Turns out it comes in two relatively small (but heavy) boxes. The larger is 6’, 20” long but not very big in the other dimensions (mine was kind of busted-up so I couldn’t get a good measurement, but around 4x4”). The second box is about 2’ x 2’ x 1’. This box contains the wheels and is probably the heavier of the two. The total weight is around 275lbs and two people can lift each box fairly easily. It should fit in most small trucks/wagons/SUV’s and probably even in a sedan with a folding rear seat (so long as the trunk is deep enough to hold the wheel box).

You probably need to buy a spare tire

Wisconsin requires by law that you carry a spare tire for your trailer. Your state may be different, but even if it’s not the law, it’s probably a good idea. This increases the cost of the trailer significantly (I picked one up for $40 with a coupon) so include this in your budget and don’t forget to pick it up while you’re at the store.

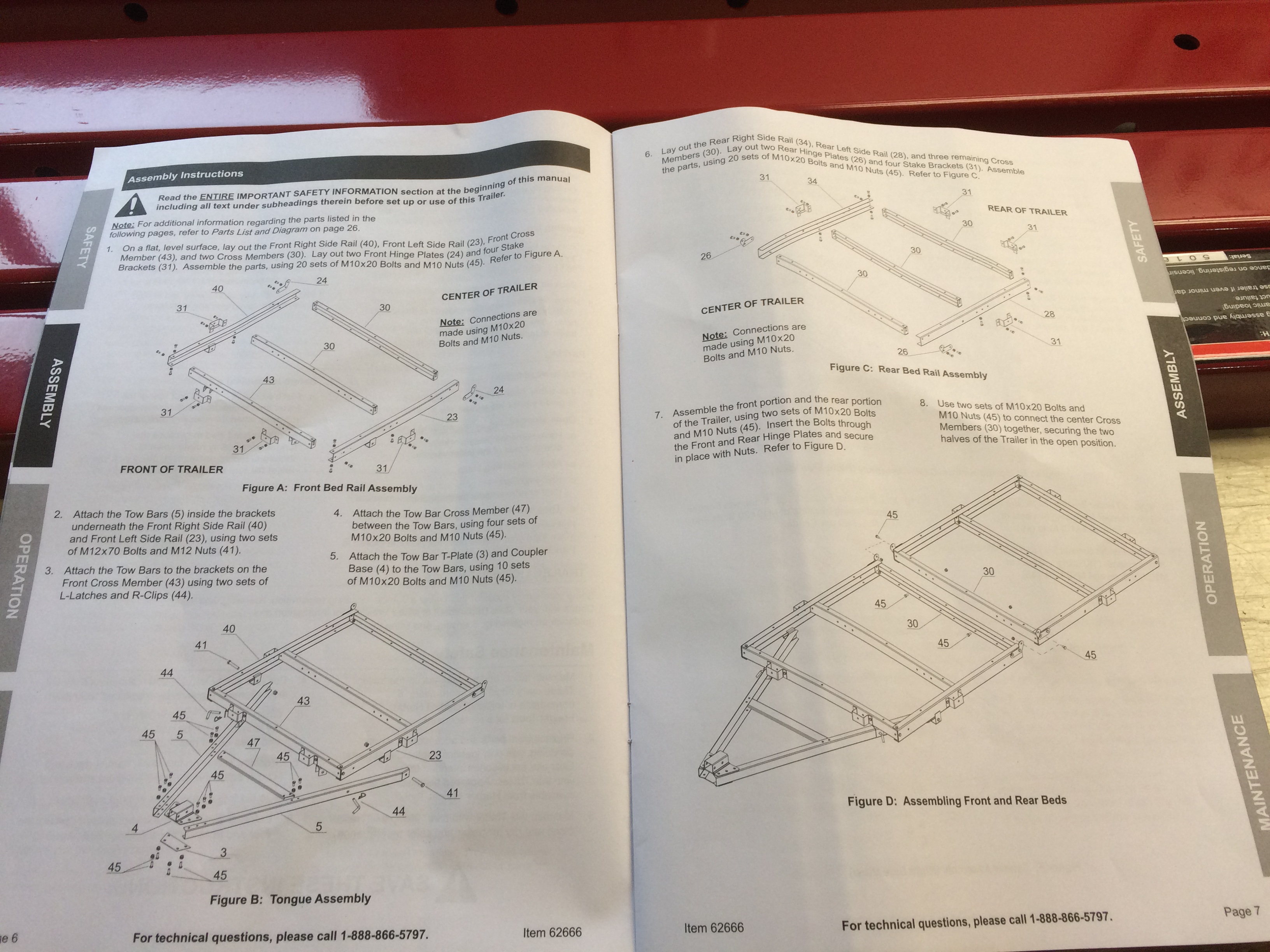

Make sure you have all the parts before you start

This advice is pervasive but it bears repeating. This thing has a lot of parts, and most of them are fairly big. If you start building it and find out you’re missing something, your choices are to spend a lot of time putting it all away (only to dig it out later when you have the missing part) or tie-up a large amount of your driveway/garage/living-room until the replacement part arrives.

This advice is pervasive but it bears repeating. This thing has a lot of parts, and most of them are fairly big. If you start building it and find out you’re missing something, your choices are to spend a lot of time putting it all away (only to dig it out later when you have the missing part) or tie-up a large amount of your driveway/garage/living-room until the replacement part arrives.  We followed this advice, found one part missing and called Harbor Freight to ask for a replacement. They told us they would call us back later when they found one. We started building with the impression that we would hear back in a few hours, but after four or five had passed we decided to call them back. The person I spoke to on the second call said they had to talk to corporate and the soonest we’d have a part is the following Monday (this was on a Saturday).

We followed this advice, found one part missing and called Harbor Freight to ask for a replacement. They told us they would call us back later when they found one. We started building with the impression that we would hear back in a few hours, but after four or five had passed we decided to call them back. The person I spoke to on the second call said they had to talk to corporate and the soonest we’d have a part is the following Monday (this was on a Saturday).  Since I needed to get this thing home and my brother probably didn’t want me using two stalls of his garage for the next few days, we had to find another solution. Fortunately my brother knows a lot of people who know how to get things done, and after a short trip to Luther’s shop we had a better-than-original replacement for the missing part.

Since I needed to get this thing home and my brother probably didn’t want me using two stalls of his garage for the next few days, we had to find another solution. Fortunately my brother knows a lot of people who know how to get things done, and after a short trip to Luther’s shop we had a better-than-original replacement for the missing part.  Had Luther not been available to us, this story would have ended a lot sooner (and would have necessitated a sequel). It’s worth mentioning that Harbor Freight never did call back, and I still don’t have a replacement for the missing part (but I like Luther’s better anyhow). Do yourself a favor and don’t start this project until you have all the parts in-hand.

Had Luther not been available to us, this story would have ended a lot sooner (and would have necessitated a sequel). It’s worth mentioning that Harbor Freight never did call back, and I still don’t have a replacement for the missing part (but I like Luther’s better anyhow). Do yourself a favor and don’t start this project until you have all the parts in-hand.

Get some help

You could probably build this yourself with the right assortment of jacks, stands, etc. but it goes a lot faster and smoother with an extra set (or two) of hands. Also, the entire trailer weighs around 275 pounds when assembled and even some of the individual parts are quite heavy. It’s not hard to imagine that you could get yourself stuck or hurt putting the thing together alone, and few things are more embarrassing than getting pinned under your own project until someone happens to find you.

You could probably build this yourself with the right assortment of jacks, stands, etc. but it goes a lot faster and smoother with an extra set (or two) of hands. Also, the entire trailer weighs around 275 pounds when assembled and even some of the individual parts are quite heavy. It’s not hard to imagine that you could get yourself stuck or hurt putting the thing together alone, and few things are more embarrassing than getting pinned under your own project until someone happens to find you.  If you look at other people’s builds, the assembly time ranges anywhere from six hours to a couple days,t hat’s quite a range. It’s not hard to see how it could take days doing it by yourself, especially if you’ve never done something like this before. A few parts runs, or any amount of re-work and the time adds up. Add to that the fatigue and frustration that comes from doing it all alone and you can see how having a friend or two who can share the load, work in parallel and laugh along with the mistakes can make a big difference.

If you look at other people’s builds, the assembly time ranges anywhere from six hours to a couple days,t hat’s quite a range. It’s not hard to see how it could take days doing it by yourself, especially if you’ve never done something like this before. A few parts runs, or any amount of re-work and the time adds up. Add to that the fatigue and frustration that comes from doing it all alone and you can see how having a friend or two who can share the load, work in parallel and laugh along with the mistakes can make a big difference.

Book some time

As mentioned above the amount of time it takes to build this trailer varies wildly, but unless you’ve built one before, plan on at least an entire day. In our case it took about 8 hours of work and 12 hours of time (travel, food, parts runs, swearing, etc.). I was also working with two people who have a lot more experience than I do with this type of project, so if you are the expert among your crew, plan accordingly.

Plan on adding a deck

Something I didn’t plan on doing immediately was adding a deck to the trailer. The kit doesn’t include this and I thought I could transport the trailer from my brother’s house to my home without it to save some time on build day. However, my friend Justin (not to be confused with my brother Justin) pointed out that due to the folding nature of the trailer (as well as the bolt-together construction) the deck is really important to the structural integrity of the thing and I probably shouldn’t be hauling it around without one.  There isn’t much to the deck, just a sheet of plywood (4” x 8’ x 1⁄2” treated in this my case) but it has to be transported, cut, drilled and bolted-on, which adds some time and cost to the project. If you’re building the trailer at home this is something that can be put-off to another day, but if you plan on taking the trailer on the road, reserve the time and money to put some sort of deck on it.

There isn’t much to the deck, just a sheet of plywood (4” x 8’ x 1⁄2” treated in this my case) but it has to be transported, cut, drilled and bolted-on, which adds some time and cost to the project. If you’re building the trailer at home this is something that can be put-off to another day, but if you plan on taking the trailer on the road, reserve the time and money to put some sort of deck on it.

Re-pack the bearings

The wheel bearings that come with the trailer are alright, but the factory lubrication is piss-poor. Plan on repacking these yourself (and if you don’t know what repacking a wheel bearing is, learn about that before you start building).