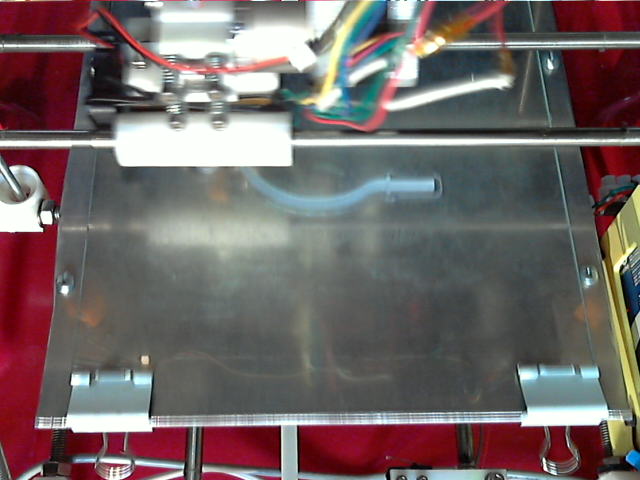

Normally I print on 3M Blue painters tape but I got a tip from the 3D Printing Google+ group that instead of using tape, a little gluestick applied directly to the print bed surface (in my case glass clamped to aluminum) works to get PLA plastic to adhere to the surface.

So far so good. Usually the first layer is a good indication of how a print is going to go, but there’s still a possibility of the print curling-up away from the surface (especially if the nozzle and bed are not perfectly “tram”, and mine is not perfect), but at this point it’s looking good.

The benefit of using this technique vs. Blue tape is that the tape needs to be replaced frequently (it wears out, and gets damaged sometimes when removing a print). Additionally it’s easier & faster to apply the glue than it is to get the tape down perfectly flat. Supposedly the glue also makes it easier to remove the print from the bed (if worse comes to worst, the glue is water- soluble).

This one’s estimated to wrap-up in about 3 hours, so we’ll see what happens and I’ll update the post when that time comes…

- Jason